Production & Logistics

Fluitronics manufactures customer-specific solutions in the field of drive technology. Accordingly, purchasing, production and logistics are geared to different products and production quantities. Typical production quantities range from 50 to 10,000 units per year.

Purchasing

Fluitronics procures in Germany and internationally. Depending on the project and requirements.

Production engineering

For customer projects, control blocks and center adapters are required in aluminum and cast iron, with special cartridge bores as well as precision bores.

Samples are manufactured in a small production area at Fluitronics, at ERC Krefeld and at one of the manufacturing partners. Machining for series production is carried out by one of the long-standing suppliers of turned and milled parts in Germany and Europe. In addition, precision manufacturing of valve housings takes place at the manufacturing site of the Herne group of companies. Cast blanks for valve production are sourced from suppliers in Germany and China.

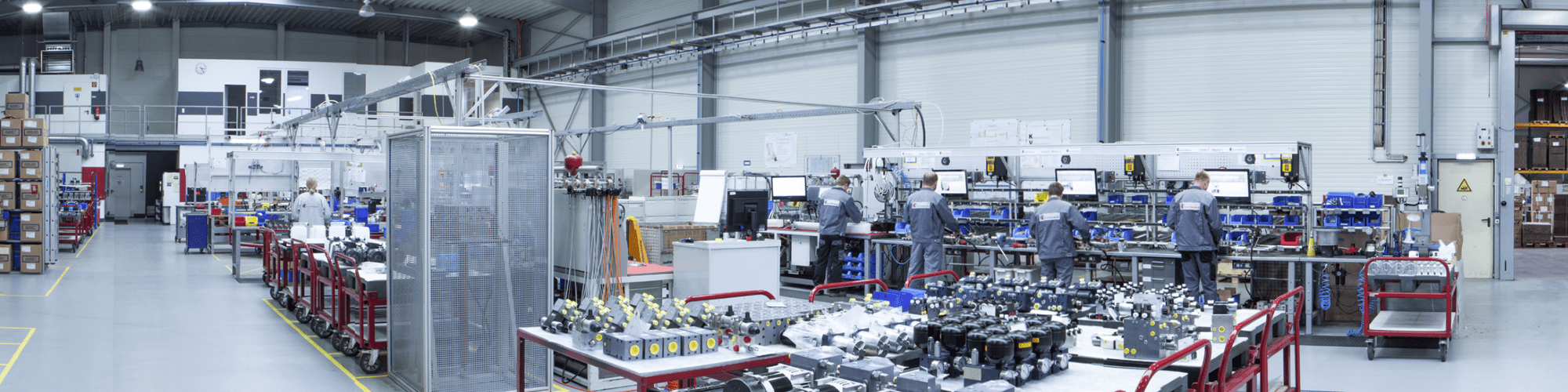

Assembly & Testing

We are specialized in assembly and joining technology.

For the assembly of control blocks and aggregates in small lot sizes, 6 individual assembly stations are available. The single workstations are equipped with electronic, monitored torque wrenches and on-screen worker guidance. The operator guidance system accesses approved shop drawings and work instructions directly on the PLM system.

An ESD-compliant assembly workstation exists specifically for the assembly of electronic assemblies.

The testing of control blocks is carried out via 3 test stands, which are supplied with up to 300 l/min and 300 bar via a central pressure supply.

For series production in large quantities, an automated and highly efficient line production with several workstations is available. Each work station is equipped with a screen, pick-by-light system and electric screwdriver including monitoring. In addition, there are automated and monitored expander setting machines (ball expanders and tear-off expanders) with force-displacement or tear-off monitoring and lubricators. In general, products are only cycled at the workstations if torques and values are within the specified thresholds.

At the end of assembly, a customer-specific end-of-line test with tank leakage test, filling, current and voltage monitoring takes place during operation. All measured values such as EOL test values and torques are stored in a database with second-by-second accuracy and can be read out later if required. Power units with CANBus interface communicate directly with the test stand, and the electronic calibration of sensors – e.g. pressure cells – is also possible directly at the test stand.

Logistics

We aim to provide our customers with individual drive solutions. This also applies to a customer-specific logistics concept. An individual labeling and packaging concept is possible as well as pallet and pallet cage deliveries or packaging in a ring winder.

For our customers, consignment stocks are just as feasible as delivery according to delivery schedule procedures.

More than 7500 different items are permanently stocked at Fluitronics in the high-bay warehouse and the small parts magazine in order to be able to manufacture customer-specific items.

And if it is ever necessary to trace parts: We have established batch tracing, i.e. based on the individual production number it is possible for us to identify and trace individual subcomponents at any time.

My name is Bernd Menzel. For many decades, I have been working around the production of hydraulic and drive components. My team and I lay an important foundation for cost efficiency and quality of our customers’ products. We are happy to meet your requirements.