Customer specific hydraulic manifolds

Control blocks range from the small “linebody” to the large, complex control block with various functions.

Screw-in valves and CETOP valves can be used, or spools can be designed directly into the control block.

Two examples are shown below, one for a cartridge solution and a “parts in body solution” with integrated spool technology in a monoblock.

Cartridge block solution

The task is to control a traction drive. A constant torque is to be delivered to all four wheels, but when cornering, the higher speed and thus the volume flow requirement of the outer wheel must be met.

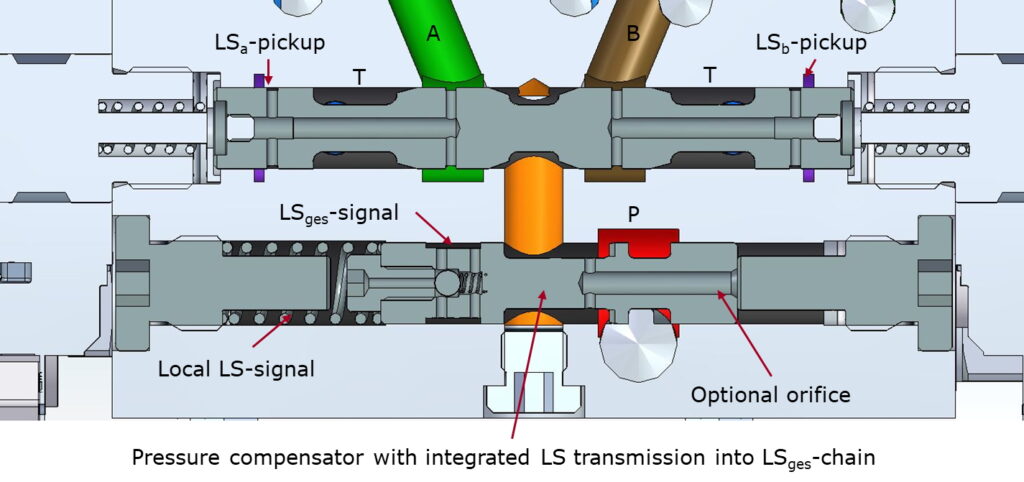

Parts in Body Solution

The task is the proportional control of several cylinders for a lifting unit. The control is electrical; due to the relatively low volume flows of <100 l/min, the functions can be controlled without pilot control. For larger volume flows, proportional pilot control must be used due to the flow forces.

The solution is designed as a so-called “parts in body solution”, i.e. the control spools run directly in the cast block. In this case, a cast blank is used which can be used to cover different variants. Alternatively, however, the solution can also be implemented in a purely drilled block.

Load compensation is required for some functions. In this case, an upstream pressure compensator is used.

In addition to pure proportional control, safety functions must be integrated into the block. These include, for example, primary pressure relief functions or secondary LS pressure relief.

Where seat tightness is explicitly required, separate cartridge seat valves are used, for example.