Jack systems of different performance classes

Fluitronics is a specialist in the development of customized solutions, including the design and manufacture of support systems of various performance classes and quantities. An example of support systems is shown below to give an idea of what is possible.

The basic task is to support a vehicle. The vehicle is to be lifted completely off its axle and leveled. In addition, the application must meet safety requirements both technically and in terms of documentation. The technical requirements are shown below.

| Größe | Wert | Einheit |

|---|---|---|

| Hublänge | 1 | m |

| Ausfahrgeschwindigkeit | 1 | m/min |

| Fahrzeuggewicht | 10 | Tonnen |

Table: Technical requirements

Layout concepts

Possible design concepts are the central unit for several cylinders and the concept of one unit per cylinder.

Central unit for multiple cylinders

In this concept, a central unit controls 2, 4 or more cylinders. All the valves required for control are located in the unit or on the cylinders.

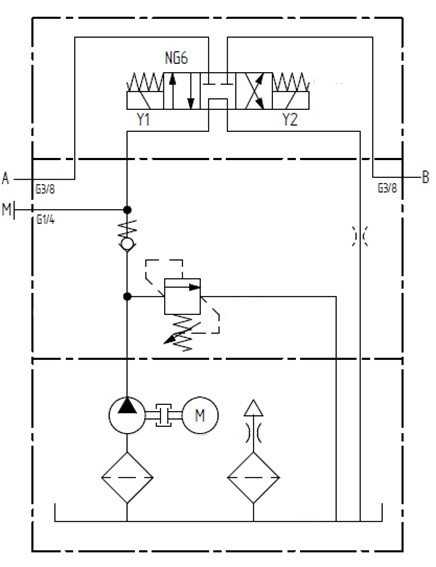

A central unit with a 4/3-way valve is shown opposite. In this case, additional isolating valves are located directly on the cylinders.

One power pack per cylinder

In this concept, each cylinder is assigned to its own power pack. Either directly integrated into the cylinder base or hosed.

Circuit concepts

Various hydraulic circuit concepts come into question, depending on the detailed requirements.

Power pack with 4/2-way valve and pilot operated check valve

The task is to ensure that the support does not collapse under load when not energized. This can be implemented via pilot-operated check valves. These are only opened when the pump builds up pressure. In the depressurized state, the check valves remain closed.

The retraction and extension of the cylinder is realized via a 4/2-way valve or alternatively a 4/3-way valve.

Power pack with 4/2-way valve and sealed solenoid seat valve

Alternatively, this function can be implemented with a solenoid seat valve. The special feature of solenoid seat valves is that they are relatively tight in the de-energized state. The cylinder cannot retract. Only when the valve is energized can the cylinder move.

The direction of travel of the cylinder is in turn controlled by a 4/2- or 4/3-way valve.