Power pack with frequency variable synchronous motor control

Variable frequency drives are used when AC motors or three-phase motors are to be operated with variable speed. This is required in fluid technology if primary control of the delivery volume flow of a pump is to be implemented in a hydraulic unit instead of secondary control via valve technology.

In addition, there are also applications, particularly in the field of e-mobility, in which variable-frequency drives are used in combination with DC power supplies.

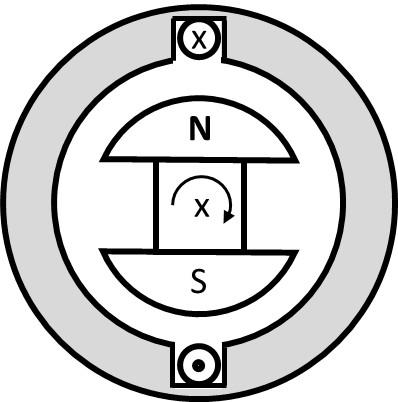

The motor types used are, for example, synchronous motors. To operate them at variable speeds, an inverter and an angle encoder are required.

Synchronous motors with inverters are used where brushed DC motors cannot be used. For example, where special requirements are placed on continuous operation, efficiency, dynamics or control quality.

Synchronous motors with angle encoders – design and mode of operation

A synchronous motor is a multi-phase AC permanent magnet motor that is usually controlled with three phases. The motors can be designed for different voltages; versions for extra-low voltages of 24 V or 48 V are available, as are versions for low voltages in the 230 V range. Fluitronics uses motors from well-known manufacturers.

The voltage level that makes sense depends on the required power. For high power requirements, it is often preferable to choose high voltages, since otherwise the current values to be carried become so high that they can no longer be handled reasonably, which also has an effect on cooling, installation space and component selection.

However, the voltage level also depends on the generally available power supply and, if applicable, requirements for manageability and potential hazards.

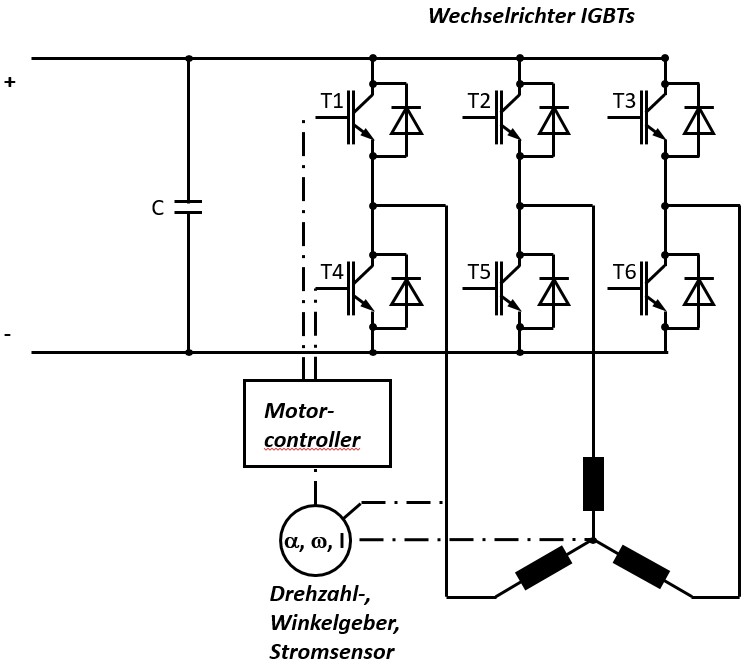

Inverter – design and function

The inverter is an essential component in customization. Communication type, control type and motor monitoring are determined by the inverter. However, the dynamics and efficiency are also significantly influenced by the inverter.

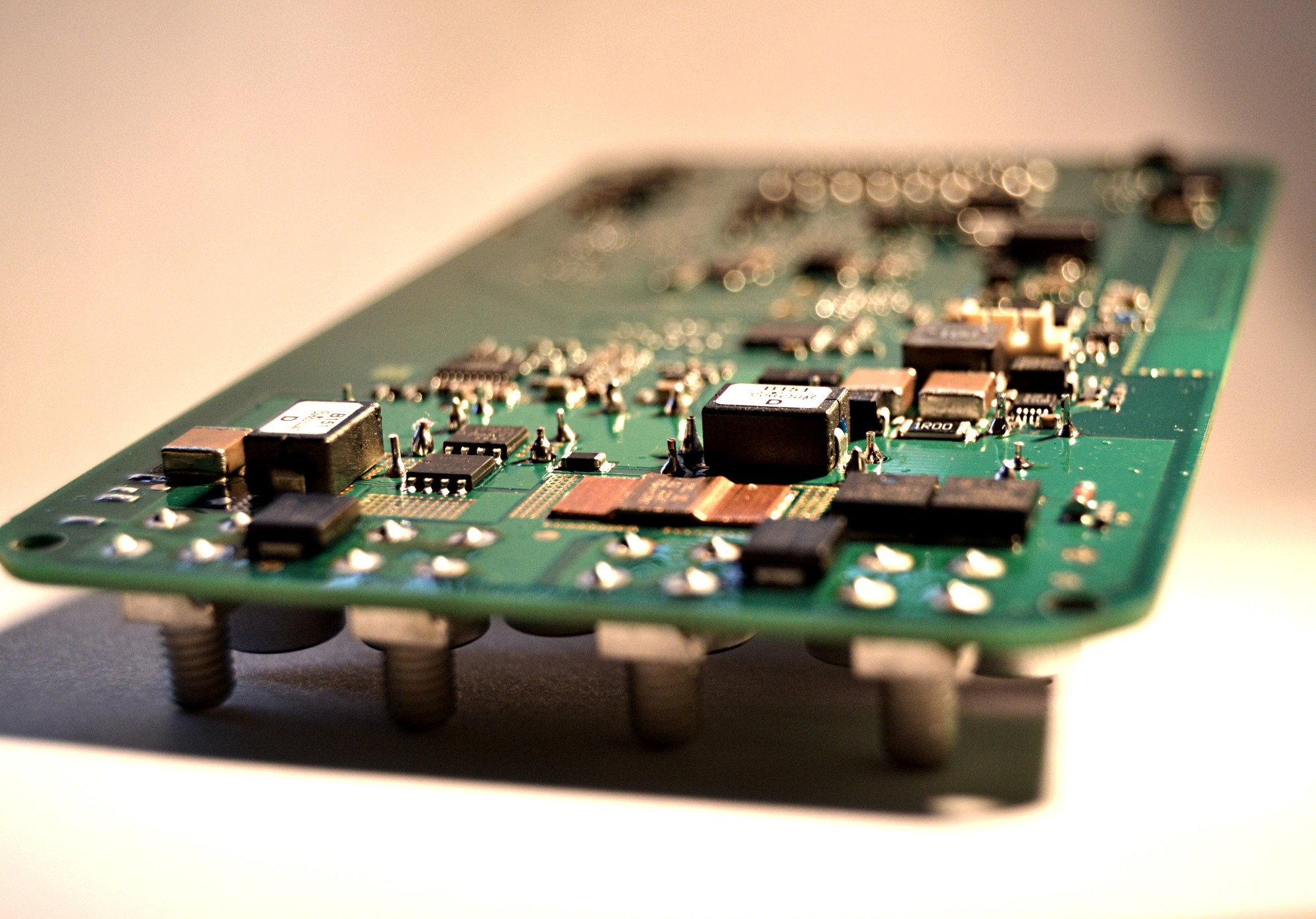

In series applications with special requirements, such as the example shown here, it may make sense to develop a customer-specific inverter board. Motivation for the own development are the number of pieces, requirements for a special, integrated design as well as requirements for communication, e.g. via CAN bus or with special protocols.

The basic structure of an inverter is shown opposite. The core of the inverter is the motor controller, which takes over the phase-precise control of the motor. This drives the power output stage via an intermediate stage, the gate driver, whose heart is a so-called MosFET. For the regulation of the phase control, the controller continuously measures the current in the 3 strings and receives information about the respective angular position and angular velocity.

Application example

In this example the task is the hydraulic control of auxiliary functions in a mobile application. The power unit should be integrated into the available 48 VDC board network. The hydraulic power requirement is 700 W in continuous operation. The task is the pressure and position control of positioning cylinders. Furthermore, the requirement is for communication via CAN bus and extensive monitoring of the system.

Typical other applications

Other typical examples in which variable-speed synchronous motors can be used are shown below

Laying drives or harvesting drives with high control dynamics and control accuracy in combination with reduction gears

In agricultural engineering, for example, laying drives (e.g. potato laying drives) or harvesting drives are used where high control quality and dynamics are required. Such drives are often implemented hydraulically on mobile agricultural machinery using hydraulic flow controllers and hydraulic motors. However, synchronous machines with frequency converters and possibly gear reduction can also be used as an alternative. The advantage is the possibility of bus communication between different laying drives and the central machine master, which communicates with the tractor e.g. via an ISO BUS common in agricultural engineering.

Belt drives with high dynamics and control quality requirements

Belt drives are used in various mobile and stationary applications. While standard drives do not have any special requirements in terms of dynamics, controllability and, if necessary, positionability and are usually operated with simple asynchronous machines, a synchronous motor may be required in special cases if the requirements for controllability, positionability and dynamics increase. A synchronous motor with intelligent inverter technology can also be useful if the motor is to communicate with other participants in the drive.

- Bild Aggregat mit Synchronantrieb

- Schnitt durch Motor mit Platine

- Bild Elektronikplatine

- Prinzipbild Schaltplan Synchronmotor

- Prinzipbild Schaltplan Umrichterelektronik

- Video Dynamische Anwendung