Electromechanical linear and rotary drives

Gearbox

Depending on the application and requirements, hydraulic solutions can be considered, but in other circumstances an electromechanical solution may also be appropriate.

In which cases hydraulic drives have advantages and where electromechanical drives are rather used can be seen in the adjacent table.

Application example low-power actuator

The gearbox

The task is linear adjustment and positioning with the aid of a low-power actuator in the 60 watt power range. The number of units is 5000 units per year.

A 3-stage spur gearbox was selected for this task. An alternative concept with worm gears was ruled out, since emergency operation in the de-energized state is not possible with the required ratios due to self-locking. For reasons of wear, metal spur gears with straight teeth are used in almost all stages. Only in stage 1/2 is one gear made of plastic in order to prevent structure-borne noise transmission from the drive to the output shaft due to the greater damping.

Plastic design

The design of the housing is implemented in plastic, since the production costs in this design are significantly lower than for alternative metal designs. At the same time, a plastic design is still possible with the resulting forces and moments.

Electric drive and control

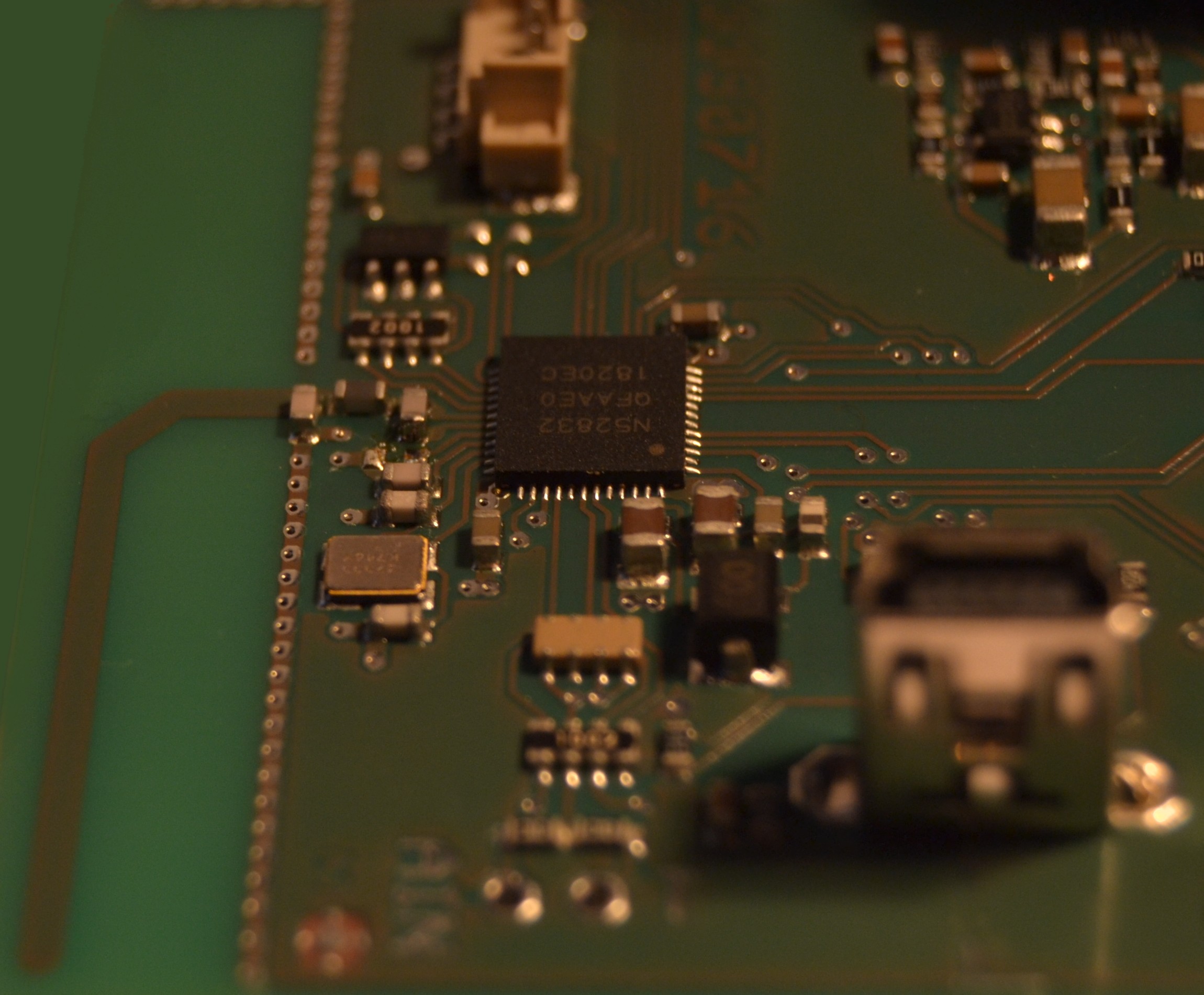

The actuator is speed-controlled with a PMDC motor. Control is provided by a circuit board with a motor full bridge integrated into the gear housing. The motor can be controlled bidirectionally via the full bridge.

The logic and control is handled by a microcontroller. A CANBus interface and additional digital inputs are available for communication. Alternatively, Bluetooth communication can be implemented on the board.

Other applications

Window and door drives

Electromechanical miniature drives are used, for example, in window and door drives. Both in spur gear design and with worm gear.

Folding mechanisms for support arms

Electromechanical miniature drives can be used in applications where support arms have to be folded, or where the position has to be detected, but where no great forces are required for the movement. It is also possible for the drive to be self-locking. This means that even with external loads, the actuator does not move when de-energized.

Control drive for valve technology in the functional safety environment

Miniature drives can also be used for valve control. This takes advantage of the fact that the drive – used as a valve drive – can be adjusted with position accuracy and position monitoring and remains unchanged even in the event of a power failure. In addition, the actuator does not close even at high volume flows. The actuator also enables the implementation of functional safety requirements.

Elektrische Vollbrücke

Steuerelektronik mit Bluetoothantenne